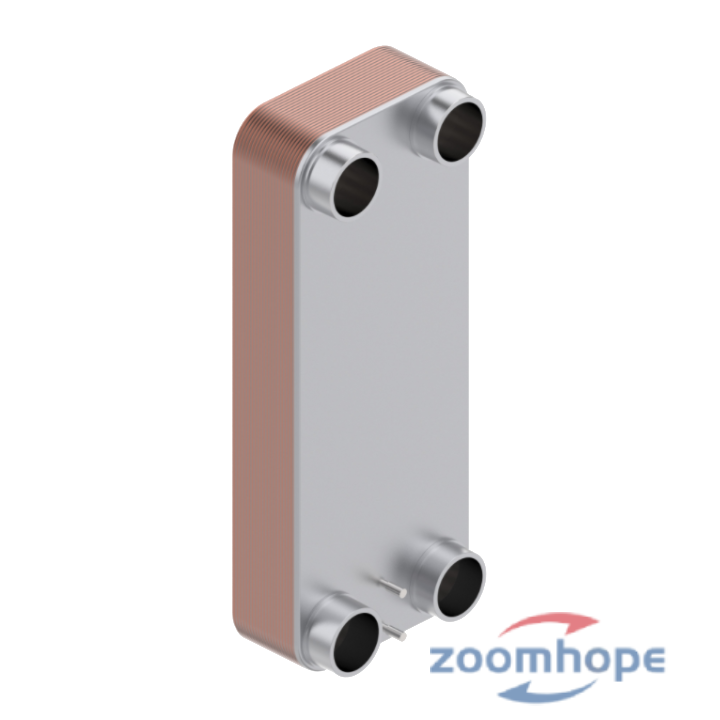

Brazed Plate Heat Exchanger

Product Information

Brazed Plate Heat Exchanger (BPHE) Overview

The Brazed Plate Heat Exchanger (BPHE) is a highly efficient, compact, and lightweight heat transfer device widely employed across various industries. It utilizes a series of thin, corrosion-resistant metal plates that are precision-stamped and alternately rotated 180 degrees before being brazed together under high temperatures to form a permanently sealed heat exchange unit.

Key Features:

Efficient Heat Transfer: High thermal conductivity and low thermal resistance enable exceptional heat exchange efficiency.

Compact Design: Minimizes space requirements, facilitating installation and maintenance in constrained environments.

Pressure & Temperature Resistance: Brazing ensures durability under high pressures and temperatures.

Easy Maintenance: Disassembles for cleaning, maintaining optimal performance over time.

Operating Principle:

BPHEs operate by circulating hot and cold fluids through alternating channels formed by the plates. Heat is efficiently transferred from the hot fluid to the cold fluid at the contact points between the plates, facilitated by the tight brazed seals and corrugated plate surfaces.

Applications:

Refrigeration & HVAC: Cooling or heating refrigerants for temperature control.

Industrial Process Heat Recovery: Recycling heat from wastewater, exhaust gases, etc., for energy efficiency.

Chemical Processing: Managing heat transfer in chemical reactions to enhance productivity and quality.

Solar Hot Water Systems: Transferring heat from collectors to storage tanks.

Boiler & Hot Water Supply: Heating water and providing thermal energy for domestic and commercial use.

In summary, the Brazed Plate Heat Exchanger's combination of efficiency, compactness, and reliability make it an invaluable asset across diverse industries, poised for continued growth and impact.