Gaskets

Product Information

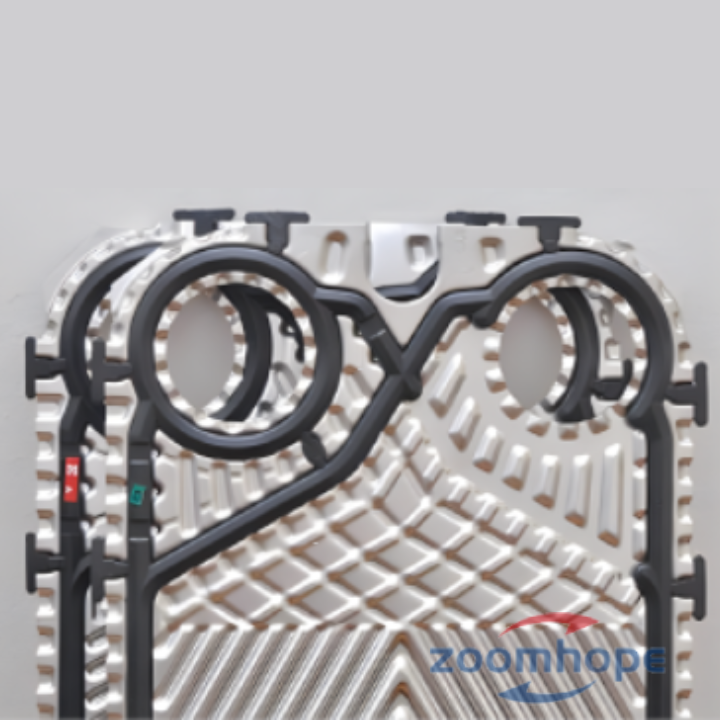

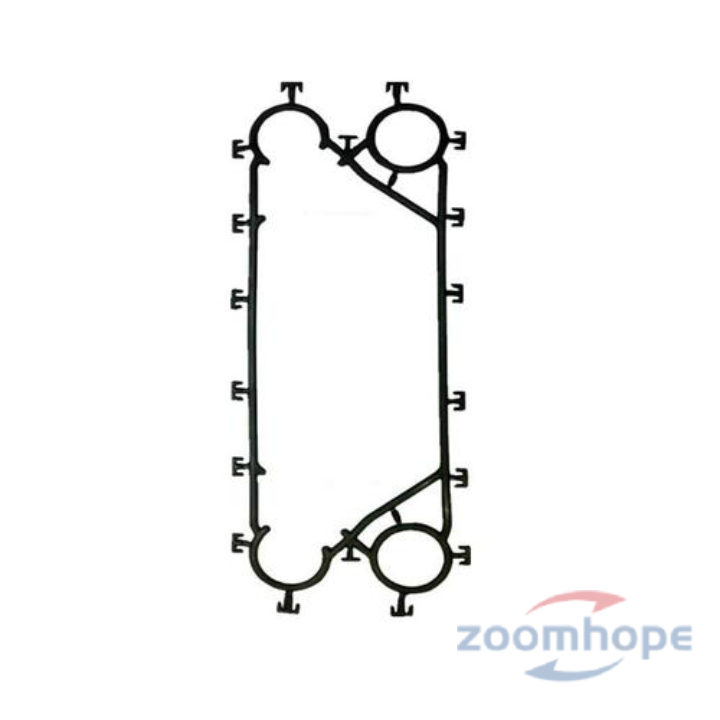

Plate heat exchanger gaskets are a crucial component in the operation of plate heat exchangers, serving as both a sealant and a flow director. These gaskets are typically made from materials capable of plastic deformation and possessing sufficient strength to ensure effective sealing and prevent medium leakage while guiding the flow as intended.

Characteristics of Different Gasket Materials

1. Nitrile Rubber (NBR) Gaskets

Features: Suitable for temperatures up to 135°C, primarily used in non-polar media such as mineral, animal, and vegetable oils. Exhibits good oil and abrasion resistance.

Applications: Ideal for the petrochemical, pharmaceutical, and other industries involving non-polar media.

2. Hydrogenated Nitrile Rubber (HNBR) Gaskets

Features: Operating range from -5°C to 150°C, suitable for sulfur-containing crude oil, H2S-mixed media, and high-temperature edible oils. Offers enhanced heat and chemical resistance.

Applications: Particularly suited for petroleum refining and natural gas processing.

3. Ethylene Propylene Diene Monomer (EPDM) Gaskets

Features: Effective up to 160°C, commonly used in hot water, steam, food and beverage processing, and dairy pasteurization. Known for its excellent aging and weather resistance.

Applications: Widely employed in food processing, beverage production, HVAC, and other industries.

4. Chlorinated Ethylene Propylene (CE) Gaskets

Features: Suitable for temperatures ranging from -20°C to 150°C, resistant to polar solvents like esters and diluted inorganic acids/bases.

Applications: Ideal for chemical laboratories and fine chemicals.

5. General-Purpose Fluororubber (GF) Gaskets

Features: Operating range up to 180°C, suitable for non-polar mineral oils, lubricating oils, and fuel oils containing alcohols. Exhibits superior chemical resistance and high-temperature tolerance.

Applications: Especially useful in aerospace, automotive, and other high-tech sectors.

6. Specialty Fluororubber (AF) Gaskets

Features: Effective between 30°C and 130°C, specifically designed for high-concentration sulfuric acid and other inorganic oxoacids.

Applications: Dedicated to industrial processes handling highly corrosive media.

Additional Benefits

High-Performance Sealing Material: Plate heat exchanger gaskets are made from high-performance materials that remain stable, resistant to deformation, aging, or damage at elevated temperatures.

Excellent Sealing Capabilities: Ensure the prevention of heat transfer medium leakage, enhancing system efficiency.

Ease of Installation: Simplify the installation process of plate heat exchangers, reducing time and costs.

Versatility: Compatible with various sizes and shapes of plate heat exchangers, catering to diverse system requirements.